In previous months we discussed the use of Barcol Hardness testers to measure and quantify the degree of cure of fiber reinforced plastics (FRP). This month we finish the discussion of FRP cure with the most accurate method, Differential Scanning Calorimetry (DSC).

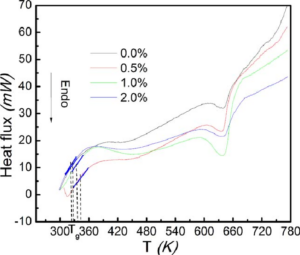

This method uses a dynamic mechanical analyzer, shown in the photo above, to monitor and graph the temperature flow of the cured resin when it is heated or cooled. A trained technician performs this test in controlled laboratory conditions and compares the sample results with properly cured resin data provided by the resin manufacturer. The graph below is from a test performed on a laminate made with polyester resin.

In terms of convenience, cost and speed, Barcol testing is the clear winner. But Barcol testing is only reasonably accurate, whereas differential scanning calorimetry (DSC) is very accurate. If Barcol test results are ambiguous or show a pattern of under cure, taking the next step and performing DSC testing is appropriate.

An important difference between Barcol testing and DSC testing is that while the latter is more accurate, it is destructive. Barcol testing does not normally injure the FRP part being tested. In DSC testing, a small sample coupon of the FRP part in question has to be removed to be tested, and the coupon is then discarded after the test. If the FRP is to be trimmed to shape after the laminate has cured, the trimmings may be DSC tested without effecting the actual FRP part. Same with any cut-outs that may be removed from the FRP as part of its later processing. Also, if it is known before lamination starts that DSC testing will be performed, it may be possible to laminate a test coupon at the same time as the FRP part is being laminated. This is allowed if all the same resins and fabrics are used the same ways in both the part and the coupon. However, in all cases of differential scanning calorimetry testing, the actual FRP part itself is not tested.

Attaining the proper cure of the resin in any FRP part is vital to attaining the desired physical properties. At Diamond Fiberglass, we Barcol test our FRP tanks often. Between the ease, low cost and speed of Barcol testing, and the accuracy of DSC testing, any FRP part can be tested to measure degree of cure.

About Diamond Fiberglass Systems and Services

Diamond Fiberglass Systems and Services has been delivering value to customers since 1986. Diamond manufactures quality, custom-engineered Fiberglass Reinforced Plastic (FRP) tanks and vessels. The company also provides field services that include general maintenance, complex turnaround installations, emergency services, and on-site FRP tank inspections. Facilities are located in Texas and Louisiana. For more information about Diamond Fiberglass Systems and Services, please visit: diamondfiberglass.com, diamondservices.com, and fibrex.com.

About Andronaco

Founded in 1994, Andronaco Industries is a Total Systems Turnkey™ provider for demanding flow control and fluid management applications. Andronaco is unique in its ability to provide field services and to manufacture a broad product line consisting of multiple materials of construction. Products include lined valves, metallic and nonmetallic piping and fittings, expansion joints, hoses, system accessories, pumps, and process and storage FRP tanks and vessels. No other manufacturer in this space brings together end-to-end flow control and fluid management product needs in combination with field services for safe and reliable operations. For more information about Andronaco Industries, please visit: www.andronaco.com.

Total Systems Turnkey™ Approach

Andronaco Industries, supported by Diamond Fiberglass Systems and Services, is a Total Systems Turnkey™ provider for demanding flow control and fluid management applications. Andronaco and Diamond are unique in that we provide field services as well as manufacture a broad product line consisting of multiple materials of construction. Our products include lined metallic and nonmetallic piping and fittings, valves, expansion joints, hoses, system accessories, pumps, and vessels/tanks. No other manufacturer in this space brings together your end to-end product needs in combination with field services for your safe and reliable operations. To learn more about the Total Systems Turnkey™ Approach, please visit: The Total Systems Turnkey™ Portfolio.